Mrz 30

At this unprecedented time, we understand the additional work the waste and recycling industries are taking on across the country.

To support this national effort, we can offer both long and short term solutions on the Pronar range of machinery.

The un-stoppable Pronar range can handle a multitude of materials including municipal waste, through wood, plastics, household clearance such as mattress and carpets, tyres, aluminium and much more.

Contact our Sales office on +44 (0)1476 568384 to discuss how this dynamic product line can work for you, with immediate delivery available.

We love supporting our customers and showcasing how our machines are enhancing their businesses.

We recently sold a Jo Beau M250 to Ollie Wilmot of Wilmot’s Tree, Shrub & Trimming Services.

Ollie was kind enough to share some photos with us of his first job with the Jo Beau, which was siding a privet hedge at a Methodist church.

Ollie said „as you can see from the final picture, the job was big and consisted of lots of overhang to fence height and went very well thanks to the Jo Beau“.

We look forward to seeing more of your work, Ollie!

For further information on any of the Jo Beau range, please contact the Sales office on +44 (0)1476 568384.

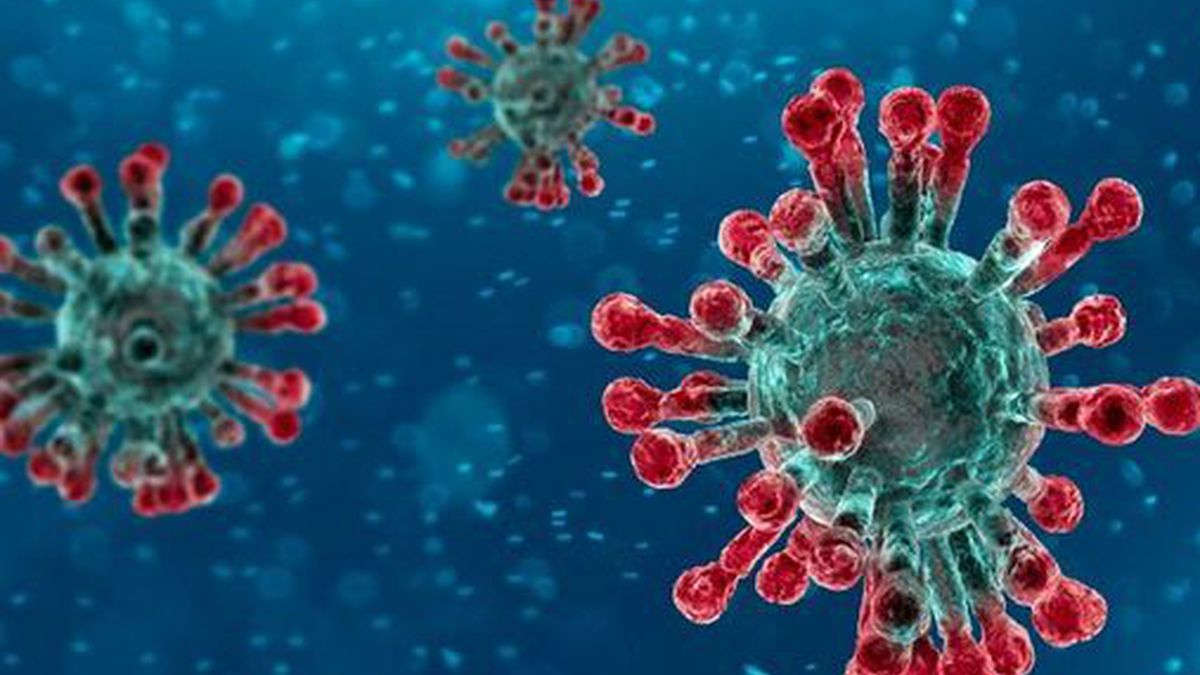

In Anbetracht der sich entwickelnden Coronavirus-Situation (COVID-19) möchten wir Sie über die Maßnahmen informieren, die wir als Unternehmen zu diesem Zeitpunkt ergreifen.

Die Gesundheit unserer Kunden und Mitarbeiter hat für uns oberste Priorität. Wir halten uns genau an die Empfehlungen von Public Health England und der Weltgesundheitsorganisation und ergreifen eine Vielzahl von Maßnahmen, um die Auswirkungen auf die öffentliche Gesundheit zu minimieren.

Unsere Service- und Vertriebsmitarbeiter kommen regelmäßig mit Kunden in Kontakt. Aus diesem Grund haben wir die Reinigung von Lieferwagen und Werkzeugen intensiviert und unsere Mitarbeiter aufgefordert, sich regelmäßig die Hände zu waschen und zu desinfizieren sowie bei der Arbeit mit Kunden Abstand zu halten.

HIER KÖNNEN SIE UNSERE RISIKOBEWERTUNG EINSEHEN

Unsere Ersatzteilabteilung und unsere Geschäfte unterliegen dem gleichen verstärkten Reinigungs- und Händewaschprogramm sowie Desinfektionsmaßnahmen, um sicherzustellen, dass wir jede Möglichkeit der Verbreitung von Krankheitserregern beim Betreten oder Verlassen unserer Räumlichkeiten minimieren.

Die Mitarbeiter wurden darauf hingewiesen, dass sie, wenn sie auch nur leichte Anzeichen von grippeähnlichen Symptomen zeigen oder in die Risikokategorie fallen, die staatlichen Empfehlungen zur medizinischen Versorgung und Selbstisolierung befolgen sollten. Wir sorgen dafür, dass das Personal in dieser Zeit umfassend unterstützt wird.

Wenn Sie ein Kunde sind, der einen Termin bei uns hat und Grund zu der Annahme hat, dass Sie oder einer Ihrer Mitarbeiter Anzeichen von Krankheit zeigen, setzen Sie sich bitte sofort mit uns in Verbindung, damit wir den Termin verschieben und eine mögliche Ausbreitung des Virus verhindern können.

Wir werden die Situation weiterhin beobachten und die Anweisungen der Regierung befolgen. Als Unternehmen werden wir alle erforderlichen Maßnahmen ergreifen, um die Gesundheit unserer Kunden und Mitarbeiter zu schützen.

Zur Information unserer Kunden, die eine kontinuierliche Versorgung mit Teilen, Maschinen, Reparaturen und Wartung benötigen, haben wir praktikable und durchführbare Notfallpläne für die Betriebskontinuität aufgestellt. Wenn Sie weitere Informationen benötigen, wenden Sie sich bitte an Hannah Miles unter der E-Mail-Adresse [email protected].

Wir danken Ihnen,

Global Recycling Solutions Ltd.

This week our Managing Director, Peter Banks, and Business Development Director, Dean Ashton, have been over in Poland with our good friends and clients Gavin and Fraser from Fletchers.

The brilliant team at Pronar hosted a spectacular Industry Forum conference and extensive trip around the Siemiatycze and Narew factories.

It goes without saying that you leave a Pronar visit in absolute awe of the dynamic development and futuristic progression seen across their factory sites.

A massive thank you to Pronar for their generosity of hosting such a wonderful event and we look forward to seeing you again very soon.

To celebrate the success of our Jo Beau ‚Technical Week‘ videos, we are running special offer promotions throughout this week and into Monday 2nd March.

Each machine comes with a Jo Beau goodie bag which includes a fleece and entry to The Arb Show in May, where we will be exhibiting the Jo Beau machines.

To give you a re-cap on the offers available, please see below. Remember to follow us on social media platforms to be first to see the upcoming offers as they are released.

If you are interested in any of the machines below, please call our Sales office on +44 (0)1476 568384 or e-mail [email protected].

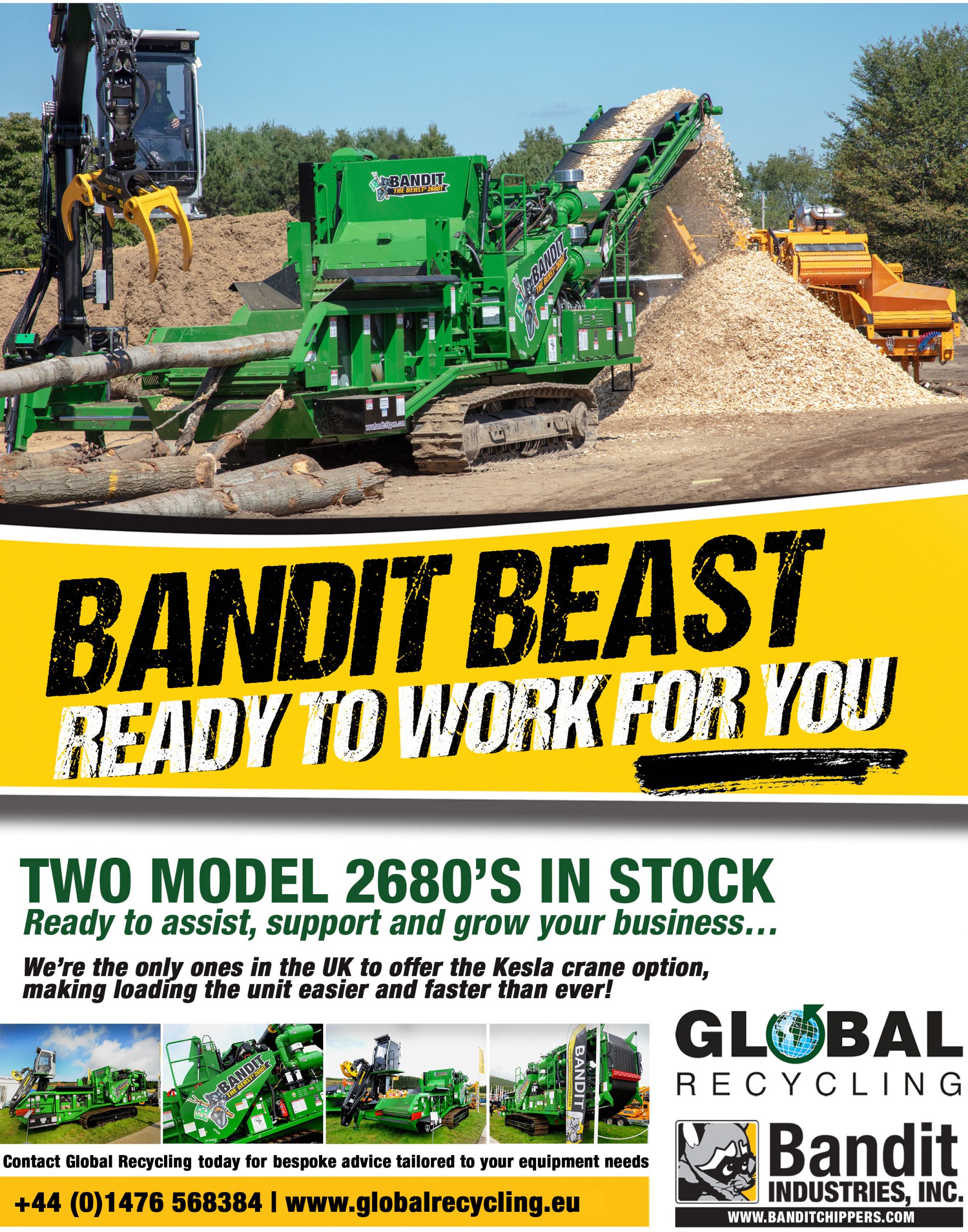

Want to know more about our showstopper, the Bandit Beast 2680? Read our informative article from Forestry Expo, currently featured on the Forestry Journal website.

This impressive machine is the only 2680 in the UK with a crane and attracts attention wherever it goes.

For further information or to enquire about a demo, please contact our Sales office on +44 (0)1476 568384.

Forestry Expo: Global Recycling

A monster of a machine that looks like it was built to command attention, the Beast horizontal grinder from Bandit Industries was a dominating presence on the Global Recycling stand, which the team was enthusiastic to talk about.

The very first Bandit chipper was built in 1983 in a 6,000 sq ft repair shop. Fast-forward to 2019 and Bandit’s complete product line offers more than 50 different machines to choose from.

Key to the Beast’s success, according to Global Recycling, is its unique cuttermill. Using a spiral pattern with a series of teeth, cutterbodies and rakers, it processes material using a cutting/splitting action versus other recyclers that attempt to bash material through hammering and grinding. The cuttermill also turns in a downward direction, which is more aggressive and less likely to discharge material back through the infeed. The rotation of the mill pulls material in, working with the feed system to provide better control of material into the machine. Material is less likely to turn or roll, and it’s cut to size better on the first pass with fewer hang-ups.

Chipper knives are available for the standard cuttermill that bolt onto knife cutterbodies. These cutterbodies can also hold standard Beast teeth for easy switching between chipping and mulching. Two dedicated chipping drums are available in lieu of the standard cuttermill for companies primarily chipping, turning the machine into a high-capacity chipper capable of producing screened chips from large-diameter material.

The solid, track-type infeed conveyor grabs and carries material for processing, keeping it on top of the conveyor, while the drag chain conveyors on rival horizontal grinders allow material to fall through the links and bind up the system. The infeed conveyor also serves as a travelling anvil, eliminating hang-ups that often occur in other horizontal grinders from the gap between the conveyor and anvil.

The Beast’s two-speed discharge conveyor ensures the discharge capacity is greater than the cuttermill’s production capacity, with height- and side-to-side-adjustable discharge systems available. A magnetic head pulley removes metal from the processed material; an optional overband magnet provides additional metal separation capability. Add-on features such as discharge funnels and chip throwers keep material focused and contained, whether building large piles or loading end-opening trailers.

The Beast 2680XP models stocked by Global Recycling Solutions feature a CAT 320L undercarriage system and weigh in at 30–40 tonnes dependent on options. The models offer 756 hp, though other engine options are available, and have an infeed opening of 890 mm x 1,524 mm.

The Rapid Advance feature allows the infeed speed to increase and decrease automatically, dependent on engine load, which keeps the engine operating at its optimal power/torque range and reduces the amount of infeed reversals. Optional features include a Kesla forestry crane and a fire suppression system.

Cutting systems available include a 30-tooth cutting head, 60-tooth cutting head (both of which can be configured with various tooling options depending on the waste stream being processed), and an 8-knife chipper drum, which can be configured to produce G30, G50, and G100 woodchip sizes. The chipper drum utilises ‘babbitted-style’ knives, allowing the knives to take the same size of cut every time, regardless of sharpening.

Andy Dudley, technical consultant, Global Recycling, explained: “The main thing about the Beast is its versatility in what products it can process. You can take a 3-m-diameter log and shred it down to 10 mm in one pass; that’s an important aspect of the machine. You don’t have to keep putting the product through to get the size smaller and smaller.

“The whole machine is radio remote controlled. We do two versions – one with a crane and a cab on it, the other without. Some guys have a version without and they’ll operate it from a log-grab on a 360 excavator, so it is a one-man operation.”

He added: “It really does live up to its name. We’ve had a couple of customers using it for clearing forestry waste on a site where there’s been harvesting and all the brash has been left behind. It goes in, they rake all the brash down the hillside, they have the machine waiting at the bottom. They load it and have bulk lorries parking underneath it. Once everything’s set up and you’ve got the correct tooling on the cutting head, you can achieve 60 tonnes an hour. They were filling bulkers within 25 minutes. It’s an absolutely awesome machine.”

Our YouTube channel is growing daily – subscribe and click the bell for regular video updates.

Over the coming weeks, we will be releasing more videos on machine models from Bandit, Pronar, Jo Beau, Norwood, Shred-Tech.. and there will also be a couple of surprises, so watch this space!

https://www.youtube.com/channel/UCEuiiVrAGxQ-qe4ddKDeK7w/

Last week we gave you Technical Tuesday with a twist – we turned it into Technical Week and featured a Jo Beau video each day, focusing on all the chipper models from the M500 down to the M100.

If you missed any of the videos, you can view them below or on our YouTube channel.

Don’t forget to leave a comment to let us know which machines you would like Andy to be showing you around next!